|

|

| |

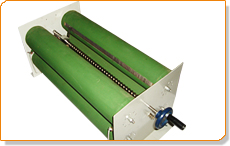

| v Wire-wound Rheostats, Hand Sliding Type |

|

|

1) Core Porcelain Tube, Non-Magnetic Non-Inductive Tubular Type. Diameter and Length of coreis given in the table below.

2) Contact Block : Squire piece made of material is fitted with contact sliders in the guide squir rod. Bright chrome plated Phosphor bronze strip which makes immediate contact with the guide rod. A backlite knob is fitted with squire piece for sliding up and down.

3) Guide Rod : Solid draven brass rod bright chrome plated squire.

4) Contact Material : Multiple brushes of Phosphors bronze strip rolled strip give springy action to the contacts.

Winding Wires : Eureka wire for low value and nichrom wire 80/20 grade for higher values.

Temperature rise : 200oC above ambient temperature

High Voltage Test : 2 KV A.C. for 1 minute between end support and any one of 3 wires terminals of the wire.

End supports : Aluminium brackets painted.

Terminals : Bright Chrome plated brass nuts and screws one at each end of Leaneer Type Wire-Wound Resistor and the third one at both the side of guide rod.

All Electrical Connectors are made from chrome plated brass material.

Rotary Sliding Rheostate, Double tube and Multiple Tubes, Non-Standard values, wattage on specific request, Available from 100 Ma to 100 Amps 0.3 ohms to 25 Kohms.

|

|

|

|

|

|

|

|

|

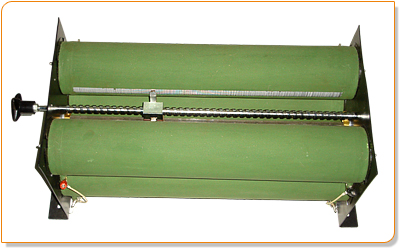

Lead Screw Motion With Handle

(4 Tubes Ganged Rheostat lsm Type)

|

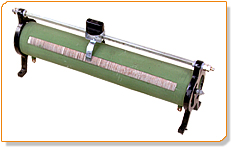

Double Tube Rheostats

|

Rheostats

|

|

|

|

|

|

|

|

4 Tubes Ganged Rheostat with

screw & knob 10 kw and above

|

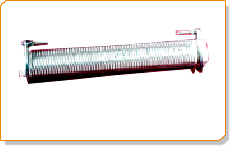

Rotary Type Rheostat with

Knob (Lead Screw Motion)

|

3 Phase Loading Rheostat

|

|

|

|

..........................................................................................................................................................................................

|

|

| |

|

v "ROHMS" WIRE WOUND RESISTORS

The 'ROHMS' RESISTORS are Manufactured after Research and planned development, Modern Manufacturing Techniques, Use of HIGH STANDARD Materials Quality Control. Proper Testing, Perfect design and process under the control of qualified and Technically well experienced hands.

'ROHMS' WIRE WOUND TUBULAR SILICON COATED RESISTORS

FEATURES :

Spot Welded Joints for reliability, Low temperature co-efficient, Low Surface temperature, Brackets available for Horizontal as well as vertical mountings, Exceptional Stability & Performance.

SPECIFICATION :

Ohmic Range 0.01 to 500K ohms. Tolerance ± 0.5%, 1%, 5% and 10%, Power Rating 0.5 W to 5000 W.

WIRE & WINDING :

Highest grade Nickel-chrome and copper Nickel Alloy wires are used Mechanically uniform, tension and required spacing. Single, Double Multiple Grade and Non-Inductive.

¡ TYPE OF RESISTORS

¡ Tubular Resistors

¡ Edge Wound Resistors

¡ Non-Inductive Resistors

¡ Ceramic Encased

¡ Fibre Card Resistors

¡ Mica Resistors

¡ Mat Resistors

RATING CONTINUOUS DUTY :

The rating given for each type of Resistor are based on a continuous duty service in free air and should be regarded as value for a single resistor mounted vertically in these conditions there will be a temperature rise of 300oC for Vitreous enameled and 200oC for silicon coated resistors.

|

|

|

|

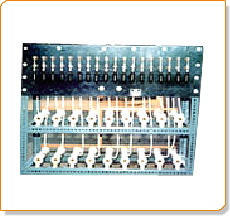

Wire-wound Resistors

|

|

|

..........................................................................................................................................................................................

|

|

| |

v MOTOR STARTING RESISTORS

TYPICAL RESISTANCE VALUES TOLERANCE ±10%

CONTINUOUS CURRENT RATINGS AT 2800C TEMPERATURE RISE |

|

|

|

|

OHMS

|

0.5

|

0.6

|

0.75

|

1

|

1.3

|

1.7

|

2.2

|

2.8

|

3.5

|

4

|

5

|

6.5

|

9

|

13

|

16

|

|

AMPS

|

28

|

24

|

20

|

16

|

16

|

14

|

11

|

11

|

9

|

9

|

8

|

6.5

|

5

|

3.8

|

3.2

|

CONSTRUCTION:

HIGH THERMAL CAPACITY GROOVED CERAMIC FORMER

OPEN TYPE WINDING

SELF LOCKING ROBUST TERMINALS

PHOSPHORUS BRONZE ADJUSTABLE BANDS.

|

|

|

| |

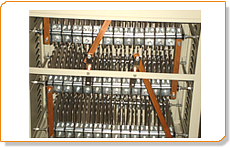

Load Bank :

Assembly of Resistors mounted in aircooled enclosure with Switches and terminals. |

|

|

|

|

|

Load Bank

|

Load Bank

|

Load Bank

|

|

|

|

Aluminium housed Resistor :

"Heat Sink type" manufactured in range of 5 watt to 250 watt.

* Non standard valves also manufactured as per customers request. |

|

| |

|

Battery Testing Load Bank (Battery Discharge Resistor Panel)

At 48 volt dc current rating 300 amps down to 5 amps can be set provided with

toggle switches for selection of load with volt & amp meter with terminals

Cooling is provided by forced air indoor installation.

Similar load banks are manufactured as per different ampere rating. |

|

|

|

|

..........................................................................................................................................................................................

|

| |

|

|

v Dynamic Braking Resistor With Enclosure Box

|

|

|

"ROHMS -( DBR) Wire wound resistor with enclosure box and external terminals.

Braking Resistors are prominently used to control motor speed. The resistor help a motor stop quickly through the process called dynamic braking. The Dynamic Braking Resistors known as DBR are used to absorb the high amount of energy generated when stopping the electric motors in Elevators, Cranes, Lifts, Wind Turbines and trains etc.

|

|

|

|

|

..........................................................................................................................................................................................

|

|

| |

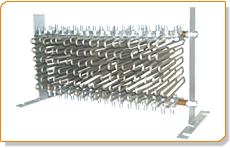

| v DYNAMIC BRAKING RESISTORS |

(STAINLESS STEEL GRID RESISTANCE) |

|

|

|

|

Continuous rating

current

|

ohms

|

Continuous rating

current

|

ohms

|

|

|

|

|

| 11 AMPS |

2.00 |

55 AMPS |

0.100 |

|

14 AMPS

|

1.00

|

62 AMPS

|

0.080

|

|

14 AMPS

|

0.750

|

80 AMP

|

0.050

|

|

20 AMPS

|

0.560

|

92 AMPS

|

0.035

|

|

27 AMPS

|

0.370

|

106 AMPS

|

0.025

|

|

37 AMPS

|

0.250

|

121 AMPS

|

0.018

|

|

45 AMPS

|

0.150

|

|

|

“ROHMS” Resistors type 'SS' are Manufactured from Stainless Steel (AISI 304) having temperature co-efficient of 0.094% per degC, wire formed grids, making them rustless, unbreakable and light in weight. there is provision at each grid to have a tapping, so that resistance value between steps could be altered. The required no of grids are put in series to get the required ohmic values. The assembly is supported of mica insulated steel rods with mica washers thus forming a stack. This stack of grid resistor can be mounted on a panel or steel rod is bolted to the two sides.

|

|

|

|

..........................................................................................................................................................................................

|

|

| |

| v ALLUMINUM HOUSED (BRAKING RESISTOR) |

|

|

|

|

specification

1 Power Ratings

Upto to 4000 Watts in Single Module.

2Ohmic Value

0.1Ω to 10KΩ

3Ohmic Tolerance

Standard ±5%. Closer Tolerances Available.

4Temprature Co-efficient

±50ppm/ºC to ±200ppm/ºC

|

5Dielectric Strength

2kV a.c. for 1 Minute

6Insulation Resistance

>2000MΩ at 500V a.c.

7Overload

5X for 5 seconds

|

|

| features

¡ 1High Power to Size Ratio.

¡ 2Specially designed for DBR applications.& other uses.

¡ 3Excellent short term overload capacity.

¡ 4Small and Sleek design. Can easily be mounted in conjusted control panels.

¡ 5High Temperature Resisting Hard Anodising Aluminium Housing.

¡ 6High power ratings can be achieved by multiplying individual resistors to form DBR banks.

¡ 7NON-INDUCTIVE types available.

|

|

|